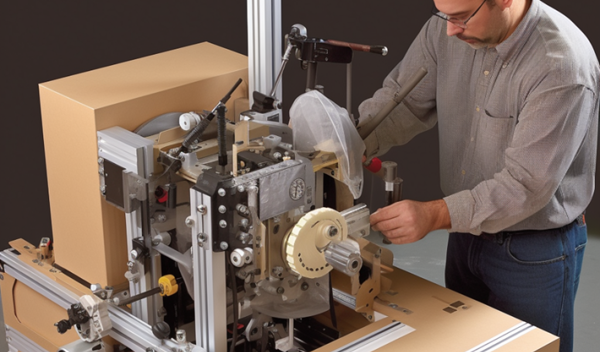

When it comes to ensuring efficient and optimal operations within your packaging line, successful maintenance and troubleshooting of equipment is key. Carton sealers and tapers are essential pieces of machinery that are used to efficiently close cardboard boxes predisposed with flaps. As such, having access to reliable strategies for maintaining these machines can help you reduce downtime associated with shutdowns or malfunctions – all while keeping your packaging line running smoothly. Read on to learn more about mastering the art of maintaining and troubleshooting carton sealer and taper issues in Australia!

Understanding the Basics of Carton Sealer and Taper Maintenance

Regularly inspecting the equipment for signs of wear or damage and replacing worn parts, such as belts and blades, will go a long way in maintaining their efficiency. Additionally, keeping the machines clean and debris-free is crucial for their smooth operation, as dust and dirt buildup can cause premature wear or malfunction. Lubricating the moving parts not only reduces friction and wear but also prevents corrosion, ultimately prolonging the life of your carton sealer and taper. By taking these simple steps to maintain your equipment, you can minimize downtime, reduce operating costs, and ensure that your packaging process remains seamless and efficient.

How to maintain Carton Sealers & Tapers

Regular inspections should focus on the condition of the tape head, blades, rollers, and drive belts, ensuring they are properly aligned and free of debris. Paying attention to the cleanliness of the sensors is equally important since they play a critical role in the accuracy of the sealer. When replacing worn components, using manufacturer-approved parts can prevent further complications and guarantee a seamless operation. Finally, adhering to a comprehensive preventative maintenance schedule based on the manufacturer's recommendations ensures your carton sealers and tapers perform at their optimal level, thereby maximizing overall productivity and profitability in your packaging operation.

Regularly Scheduled Preventative Maintenance for Carton Sealing Machine

The importance of regularly scheduled preventative maintenance for a carton sealing machine cannot be overstated. A well-maintained machine not only ensures optimal performance but also significantly increases the machine's lifespan. By diligently adhering to a maintenance schedule, you can avoid costly disruptions to your production process, saving both time and resources in the long run. This level of professional commitment to your equipment translates into improved efficiency in your packaging operations and more seamless integration of this vital machinery into your overall production process.

Here are some key benefits of preventative maintenance for your carton sealing machine:

-

Increases Machine Life

Regular preventative maintenance can significantly increase the life of your carton sealing machine. By identifying and addressing small issues before they become major problems, you can avoid costly repairs or replacements and extend the life of your machine.

-

Reduces Downtime

-

Improves Machine Efficiency

-

Increases Operator Safety

So, what should you include in your regularly scheduled preventative maintenance for your carton sealing machine? Here are some key steps:

-

Daily Cleaning: Wipe down the machine daily to remove dust and debris that can affect its performance.

-

Lubrication: Keep moving parts lubricated to prevent wear and tear and ensure smooth operation.

-

Inspection: Regularly inspect the machine for signs of wear and tear, loose or damaged parts, and other issues that could lead to breakdowns.

-

Replacement: Replace worn or damaged parts as needed to keep the machine operating efficiently.

-

Calibration: Calibrate the machine regularly to ensure that it is operating at peak efficiency.

Additionally, the benefits of timely maintenance extend to enhanced safety for your workforce and a reduction in the risk of equipment malfunctions that could lead to unnecessary downtime. Ultimately, investing in regular preventative maintenance is an investment in the success and longevity of your business operations.

Identifying and Resolving Common Issues with Carton Sealing and Taping Machines

Identifying and resolving these common issues can not only save time and resources but also maintain the reliability and precision of these essential tools in the packaging process.

Here are some common issues you may encounter with your carton sealing and taping machines, along with some tips for resolving them:

-

Inconsistent Taping

-

Jammed Tape

-

Poor Tape Quality

-

Machine Jams

-

Noisy Operation

Regular maintenance and timely replacement of parts can mitigate these risks. Furthermore, misaligned cartons or inconsistent tape application can also hinder a seamless packaging operation. By staying proactive in addressing these concerns, such matters can be quickly resolved, allowing for a smooth, uninterrupted workflow, and ultimately enhancing the overall packaging process's efficacy and quality.

Common problems with Carton Sealers & Tapers and their causes

Carton sealers and taper machines often encounter a variety of common problems that could adversely impact productivity, resulting in delays and increased costs.

-

Lack of Maintenance

-

Worn or Damaged Parts

-

Incorrect Tape Tension

-

Misaligned Tape Rolls

-

Using Low-Quality Tape

If any of these issues arise, it's important to address them promptly. This can involve seeking professional help or making adjustments on your own, depending on the severity of the issue.

Tips for fixing and Troubleshooting Carton Sealing Equipment

First and foremost, always make sure to carefully examine your machine's settings and double-check if everything is calibrated correctly. This simple step could be all that's needed to resolve the issue. Additionally, pay close attention to the condition of your sealing tape, as wear-and-tear or poor-quality tape can significantly affect the machine's performance. Regular maintenance and parts replacement can also keep your carton sealing equipment running smoothly, so ensure that the machine is inspected and serviced periodically. Finally, consider reaching out to industry peers, online forums, or the equipment manufacturer for advice and best practices regarding troubleshooting and fixing carton sealing equipment. With these essential tips in mind, you'll be better equipped to handle any issues that arise, ensuring optimal functionality and efficiency throughout your production process.

5 Tips for Optimising Carton Sealer & Taper Performance

To begin, selecting the appropriate sealer and taper system, tailored to the size and type of cartons being used, is a fundamental step in enhancing productivity. Regular maintenance, including cleaning and lubricating moving parts, contributes significantly to prolonging the lifespan of the equipment and maintaining its performance. Additionally, choosing the right packaging tape with the proper adhesive and thickness can make a noticeable difference in sealing effectiveness while reducing waste by preventing tape breakage. Gradually training your employees on the operation of the machines and stress-management techniques can lead to fewer mishaps and reduced downtime.

Here is a more in-depth tips for fixing and troubleshooting carton-sealing equipment:

-

Check for Obstructions

Clear away any tape or debris that may be preventing the machine from working properly. Common areas to check for obstructions include the tape roll area, the feed rollers, and the cutting blades.

-

Check Tape Roll Alignment

Misaligned tape rolls can lead to tape feeding issues and uneven taping, causing cartons to open during transport. Ensure that the tape roll is properly aligned with the machine's feeding mechanism. Adjust the tape roll position as needed to ensure proper alignment.

-

Adjust the Tape Tension

Tape tension is crucial to proper carton sealing. If the tape tension is too high, it can cause cartons to buckle or warp, leading to improper sealing. On the other hand, if the tape tension is too low, it can cause the tape to slip or not stick properly, leading to incomplete or ineffective sealing. Adjust the tape tension to ensure that the tape is applied with the correct amount of pressure for optimal sealing.

-

Inspect Machine Parts

Regular inspection of the parts of your carton sealer is essential to identify any signs of wear or damage that may be affecting the machine's performance. Check the feed rollers, the cutting blades, the motor, and any other moving parts for wear or damage. Replace any worn or damaged parts immediately to prevent further problems and ensure that the machine operates correctly.

-

Use High-Quality Tape

Using low-quality tape can lead to issues with carton sealing equipment. Low-quality tape may not have enough adhesive, or the adhesive may not be strong enough to keep the carton sealed during transport. Always use high-quality tape that is appropriate for your machine to ensure consistent, reliable taping. Using the right tape can also help to extend the life of your carton sealer and prevent unnecessary wear and tear.

Overall, effective optimization of your carton sealer and taper involves a combination of selecting the right equipment, regular maintenance, utilizing proper materials, and empowering your workforce with the necessary knowledge and skills.

When to seek professional help for Carton Sealer & Taper Issues

There comes a time when every business that relies on shipping and packaging must assess the efficiency of its Carton Sealer & Taper operations. While these machines generally provide consistent and secure sealing, it is crucial to recognize the signs that indicate a need for professional assistance. Issues such as frequent jamming, uneven or lose sealing, and increased machine noise could signal underlying problems that may significantly impact productivity and overall product quality. Promptly seeking professional help in these instances not only resolves the issue at hand but also mitigates potential future complications, ultimately saving time and resources. Additionally, it's essential to schedule regular maintenance checkups with a trusted technician, ensuring the longevity of the equipment and maintaining a seamless packaging process. Remember, investing in professional assistance is an investment in the success of your business.

Best Practices for Storing, Shipping and Disposing of Used Cartons Sealing Machinery

-

Storing:

To store used carton sealing machinery, it's important to keep it in a dry and secure location that is protected from direct sunlight and extreme temperatures. This will help prevent rust and damage to the machinery over time. You should also cover the machinery with a protective cover or tarp to prevent dust and debris from accumulating on the machinery. Finally, make sure the machinery is stored on a level surface to avoid any damage from shifting or tipping.

-

Shipping:

When shipping using carton sealing machinery, it's important to take steps to ensure that it arrives at its destination in good condition. This means that the machinery should be properly secured and packaged to avoid any damage during transit. Use sturdy and durable packaging materials, such as bubble wrap or packing peanuts, to provide cushioning for the machinery. You should also label the package clearly with appropriate shipping labels and instructions to ensure that it is handled properly during transport.

-

Disposing of:

Disposing of used carton sealing machinery should be done by local regulations and guidelines. This may involve consulting with local waste management authorities to determine the appropriate method of disposal. If possible, consider recycling or donating the machinery to a local charity or organisation to reduce waste and promote sustainability. This can be a good way to get rid of old machinery while also supporting a good cause.

In conclusion, maintaining carton sealers and tapers is essential to ensuring the high performance of the operations. It is not just about fixing common issues with these machines but also understanding the basics of their maintenance and implementing pre-planned preventative plans. By employing best practices for storing, shipping, and disposing of used cartons and following instructions to fix any critical issues arising from them, operators can keep these machines running in top condition at all times. If any need arises where professional help is required to resolve more major issues beyond a single user's scope, then certified technicians should be consulted. Overall, with proper care and knowledge, carton sealers and tapers can serve your business efficiently without causing you any hassles or headaches.