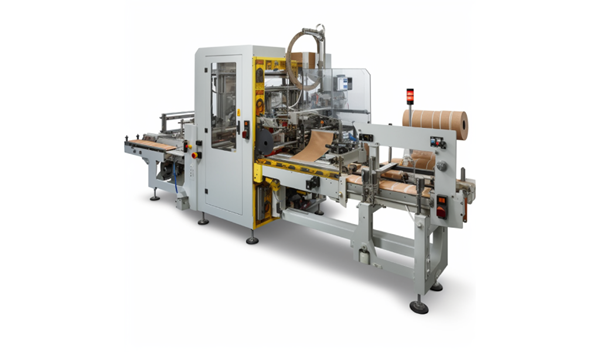

Packaging is the final step in a product’s journey. It’s crucial to protect your product and make it appealing to consumers by choosing the right materials, printing techniques, and label design. However, one of the most important aspects of any package is how it closes. A carton sealer or taper can help you ensure that your products stay safe during storage and transit.

There are many different types of carton sealers on the market today

There are many different types of carton sealers on the market today, each with its unique benefits. Some are manual and some automated, while others can be used for sealing and taping or only sealing. Some will seal one carton at a time while others can do multiple at once. How do you know which type is right for your business?

As with all packaging equipment purchases, it's important to consider how much use your new machine will get throughout its lifetime and how much it would cost if repairs were needed down the road (or even during warranty). If a product isn't working properly right out of the gate or breaks down after just a few months' use, this could result in lost profits due to downtime costs associated with having someone come out periodically to check up on things like tape rolls getting low so they don't run out unexpectedly mid-job--which could lead customers away from returning later down the road when there's no tape left!

Integrating carton sealers and tapers into your packaging line is an important step for your business.

Integrating carton sealers and tapers into your packaging line is an important step for your business. If you're shipping large quantities of product, integrating carton sealers and tapers into your packaging line will help ensure that all products are properly sealed before they leave the warehouse.

Considerations for optimising your packaging line with carton sealers and tapers include:

- Space availability: You'll need enough space to fit both machines on the same line without disrupting production flow or slowing down workers' productivity by having them move between two separate machines every time they need to change tasks.

- Cost-effectiveness: Consider whether it makes more sense from an economic standpoint to purchase one big machine rather than two smaller ones--especially if those smaller machines are going to be used only occasionally (e.g., during peak seasons).

- Product safety: If you're packaging food, cosmetics or other consumable goods (such as toiletries), the integrity of your packaging should be paramount. You won't want to take any risks with leaks or spills that could potentially cause harm to consumers.

- Ease of use: If you have a small staff and need to minimize labour costs, it's worth your time to look into machines that require little or no training or special skills. You may also want to consider purchasing a machine that comes with automatic calibration features so that workers don't have to manually adjust settings every time they change jobs.

How to integrate Carton Sealers & Tapers into your existing packaging line

Before you begin to integrate carton sealers and tapers into your packaging line, it's important to consider how they will fit into the overall process.

The first step is determining where you want to incorporate these machines on your packing line. The ideal location is between the palletizer and the shrinks wrapper (if one exists). This ensures that all boxes are properly sealed before being wrapped with plastic film for shipping purposes.

When determining which type of sealing system would be best for each application, take note of its performance capabilities: speed, accuracy and reliability are key factors when choosing between manual or automatic options. Additionally, consider whether or not an operator will need additional training before operating this equipment for him/her not only understand its functions but also to get comfortable using it effectively enough so as not to affect production rates negatively by slowing down due to inexperience or lack thereof knowledge about how things work together properly within each workflow stage.

Benefits of integrating Carton Sealers & Tapers into your packaging line

The benefits of integrating Carton Sealers & Tapers into your packaging line are numerous. They include:

-

Reducing costs by replacing manual labour with automated equipment that not only performs the same tasks but also does so more efficiently.

-

Increasing efficiency by automating processes, which allows you to produce more packages per hour than before. This means more packages in less time, which translates into greater productivity for your business!

-

Enhancing quality by eliminating human error from packaging operations and reducing the chance of human error during product assembly.

-

Safer working conditions for employees because they don't need to handle heavy boxes or move them manually around an assembly line anymore--the machines do all the work! You'll also save money on workers' compensation claims because fewer injuries occur when using automated equipment compared with manual labour methods (and if any damages do occur at all then they're usually less severe).

You'll also save money on workers' compensation claims because fewer injuries occur when using automated equipment compared with manual labour methods (and if any damages do occur at all then they're usually less severe). Lastly, you'll enjoy higher profit margins because the machines pay for themselves over time by reducing your costs.

Considerations for optimising your packaging line with Carton Sealers & Tapers

When considering how to integrate a carton sealer into your packaging line, there are several factors to consider. The first is the size of your carton sealer and its corresponding footprint in space. As you may know, there are both manual and automated versions of these products available on the market today; each type has its advantages depending on the needs of your business.

Next comes a cost: while manual models tend to be less expensive than their automated counterparts, they also require more labour which can add up over time if you're sealing large boxes at one time.

Finally, and perhaps most importantly, you'll want to consider how many boxes will need sealing before deciding which option makes sense for you!

How to Properly Seal and Tape Cartons for Shipping

The following are some tips for proper sealing and taping cartons:

- For shipping, use a double-sided tape that is strong enough to withstand the rigours of transit, but not so strong that it cannot be easily removed by the customer.

- For storage, use single-sided tape that will leave no residue if removed. This is important because you may want to reuse your boxes at some point in the future.

- For retail, consider using clear tape so customers can see what's inside their packages before they buy them!

- For food service applications like restaurants or caterers who ship perishable items like fresh produce or meat products across state lines (or even within cities), there are specific regulations regarding how these items must be packaged before shipping them offsite via trucking companies such as FedEx Ground or UPS Ground Delivery Service; this means double bagging each item inside its plastic baggie filled with ice packs until reaching the destination where temperatures remain constant throughout the delivery process without any temperature fluctuations caused by opening doors.

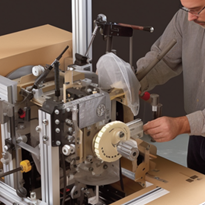

How to train employees on using Carton Sealers & Tapers in a packaging line

Training is a crucial component of the successful use of carton sealers and tapers. Make sure that your employees are trained on how to use the equipment, as well as how it functions within your packaging line.

To train employees on using carton sealers and tapers:

- Provide training manuals or videos that demonstrate how each piece of equipment works in action. This can be done through an online portal where users can access training materials at any time from anywhere, which makes it easier for everyone involved in production processes (including those who are not normally involved in packaging).

- Have someone present during the initial setup so they can answer questions about set-up procedures and troubleshooting issues that arise during operation. This ensures a smooth operation from start-up until maintenance needs attention again later down the road when something breaks down unexpectedly due to lackadaisical maintenance practices by previous workers who didn't know any better!

In conclusion, integrating carton sealers and tapers into your packaging line is an important step for any business looking to improve efficiency, reduce costs, and enhance the quality of its products. By considering factors such as space availability, cost-effectiveness, product safety, and ease of use, you can optimise your packaging line and ensure that your products are properly sealed and prepared for shipping. Additionally, properly training your employees on how to use the equipment and maintaining regular preventative maintenance on your machines can help avoid common issues and ensure the longevity of your equipment. Remember, when it comes to packaging, the final step is just as important as the rest of the process.