If you're already familiar with carton sealers and tapers, you know how crucial these devices are for ensuring that your products remain safe and secure during transit or storage. However, with so many different models and brands available, it can be challenging to find the one that's best suited for your specific needs. In this buying guide, we'll take a deeper look at the key factors you should consider when shopping for carton sealers and tapers, so you can make an informed decision and choose the right tool for your business or personal use.

Carton Sealers & Tapers: How Are They Typically Used?

As a professional in the packaging and shipping industry, you are likely aware of the importance of sealing and closing packages securely to prevent damage to their contents during transit. While manual methods of sealing cartons may seem sufficient, they can be time-consuming and prone to errors, leading to inefficient and inconsistent results.

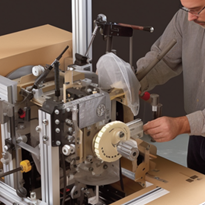

This is where carton sealers and tapers come in. These machines automate the process of sealing cartons and packages, providing consistent, reliable, and efficient results. With carton sealers and tapers, you can increase the speed and accuracy of your packaging operations, saving time and reducing the risk of damage to your products.

Moreover, carton sealers and tapers come in different types and models, designed to suit different packaging needs and requirements. From manual to fully automatic models, there is a carton sealer and taper for every packaging operation, allowing you to customize and optimize your sealing process according to your specific needs.

Investing in a carton sealer and taper is an investment in your packaging and shipping operations equipment's efficiency and effectiveness, saving you time and reducing the risk of product damage. Whether you are in e-commerce, manufacturing, or distribution, carton sealers and tapers can help you optimize your operations, providing reliable and consistent results every time.

4 Factors to Consider When Purchasing a Carton Sealer & Taper

When it comes to purchasing a carton sealer and taper, there are a few important factors to consider.

- Firstly, the type of carton sealer and taper you choose is crucial. There are different types available, including manual, semi-automatic, and fully automatic, and each type has its advantages and disadvantages. You'll need to consider your packaging volume, frequency, and the complexity of your sealing requirements when selecting the type of carton sealer and taper.

- Another important factor to consider is the production speed of the machine. If you have a high volume of packages to seal and ship, you'll want to ensure that the machine's speed and output rate meet your requirements. Additionally, the seal quality is an important consideration. The machine should produce consistent and strong seals that can withstand the rigours of transportation and handling. Look for machines with adjustable settings that allow you to control the seal's strength and quality.

- Ease of use is also a critical factor to consider. Look for machines with intuitive controls and minimal setup requirements. Consider the ease of changing tape rolls and maintaining the machine, as this can impact your productivity and efficiency.

- Finally, price and warranty are essential factors to consider. The price of a carton sealer and taper can vary significantly depending on its type, features, and manufacturer. It's important to compare the prices of different models and brands and consider the machine's warranty and after-sales support. Look for machines with a good warranty and customer support, as this can help you address any issues that may arise after purchase.

By considering these five factors when purchasing a carton sealer and taper, you can ensure that you choose a machine that meets your packaging needs, is easy to use and maintain, produces consistent and strong seals, and is within your budget.

Different Types of Carton Sealers & Tapers and Their Uses

There are several types of carton sealers and tapers, each with its specific purpose.

-

Manual Carton Sealers & Tapers

-

Semi-Automatic Carton Sealers & Tapers

-

Automatic Carton Sealers & Tapers

-

Uniform Carton Sealers & Tapers

-

Random Carton Sealers & Tapers

Choosing the right type of carton sealer and taper depends on your packaging needs, volume, and budget. Manual carton sealers and tapers are ideal for low-volume packaging needs, while semi-automatic and automatic carton sealers and tapers are suitable for moderate to high-volume packaging needs. Uniform and random carton sealers and tapers are designed to seal and tape uniform and random-sized cartons, respectively. By understanding the different types of carton sealers and tapers and their uses, you can make an informed decision and choose a machine that meets your packaging needs.

Benefits of Using Carton Sealers & Tapers

The benefits of using carton sealers and tapers are numerous. They can save you money and improve efficiency in your packaging process, as well as prevent product damage, increase shelf life and reduce waste. This will result in increased profitability for your business:

-

Reduce labour costs - Carton sealers and tapers are easy to use by anyone with minimal training, which means that they can reduce the need for skilled labour at a time when many companies lack experienced workers or find it difficult to hire them because of high unemployment rates. This can save money by reducing payroll expenses while increasing productivity at the same time!

-

Improve efficiency - Another way that these machines help businesses is by improving efficiency; they allow one person (or sometimes even just one machine) to perform multiple tasks simultaneously instead of having several people do each part individually over time--this helps keep pace with demand while decreasing bottlenecks caused by waiting times between tasks being completed

-

Reduce product damage - When you use carton sealers and tapers, you can reduce the risk of product damage during shipping by preventing air from entering the package and spoiling food items or other products that are sensitive to temperature changes. This can help ensure customer satisfaction since they will receive their purchases in better condition than if they had been shipped without this protection! Increase shelf life - Using these machines can also extend the shelf life of your products while reducing waste by keeping them fresh longer.

This is because they help prevent air from entering the package, which can cause damage and spoilage over time. In addition, sealing machines help protect against moisture infiltration that can lead to rusting or corrosion of products like electronics or tools that are stored in boxes for long periods before being sold.

How to Choose the Right Carton Sealer & Taper

When you're shopping for a carton sealer and taper, it's important to consider several things. Here are some of the most important factors:

-

Capacity: This refers to how much product can be sealed at once. If you need to package large quantities of items, look for a machine with a high capacity.

-

Speed: The speed at which an item passes through your machine will determine how many units you can produce per hour or minute (depending on the model). If speed is important, look for one that works quickly without sacrificing quality or consistency in its performance--and keep in mind that some models have adjustable speeds so they can accommodate different types of products effectively while still meeting efficiency goals!

-

Power: When considering power requirements before making your purchase decision, think about how much force is required during sealing operations-for example, if there's heavy pressure needed when applying tape then perhaps something like an electric motor would be better suited than one powered by hand because it won't strain users' wrists as much over long periods.

-

Footprint: It's important not only how big each component is but also how much space they occupy together when put together; this includes everything from size/shape (square vs circular), weight per unit volume/area etcetera so make sure there's enough room available where ever possible before making any commitments!

Common Mistakes to Avoid When Choosing a Carton Sealer & Taper

Here are some common mistakes to avoid when choosing a carton sealer:

- Not considering the volume of cartons to be sealed. If you're going to be sealing large numbers of small cartons, then a manual machine may be better suited than an automatic one.

- Not considering the number of cartons per minute (CPM). Your equipment must be able to keep up with demand, otherwise, it will become more costly and time-consuming than necessary.

- Not considering the size and thickness of the product being sealed. Some machines can only handle certain sizes or thicknesses; others have adjustable settings so they can accommodate different products without having any issues along the way!

Budget Considerations When Buying a Carton Sealer & Taper

Budget considerations are also important. As with most equipment, the price of a carton sealer and taper will vary depending on its features. If you want to buy a high-quality machine that will last for years, then expect to pay more than if you're only looking for something temporary or basic. However, the cost of a carton sealer and taper can vary significantly, depending on the type and features of the machine. In this article, we'll discuss budget considerations when buying a carton sealer and taper.

-

Machine Consumables and Features

The next thing to think about is: how much tape does each job require? What kind of glue should be used with your chosen machine (if applicable)? Are there any other supplies that could be necessary depending on what kind of product packaging needs sealing shut or taping together?

The features of a carton sealer and taper can also affect your budget. Machines with advanced features, such as automatic adjustment to carton sizes, can be more expensive than machines with basic features. However, advanced features can help increase your packaging efficiency and reduce labour costs, making them a worthwhile investment in the long run.

-

The Sealer Brand

The brand of the carton sealer and taper can also affect the cost. Established brands with a good reputation and high-quality machines are likely to be more expensive than lesser-known brands. However, investing in a reputable brand can ensure the reliability and longevity of the machine, ultimately saving you money in the long run.

-

Maintenance Costs

Then there are maintenance costs--how often do parts need replacing and how much will they cost when they break down during use? Are there any safety measures built into these machines that require regular maintenance checks before use (like checking air filters) so as not to cause injury during operation; if so, who pays for these checks - buyer or seller/manufacturer respectively; does this depend on whether part breaks down before purchase date occurs versus after purchase date has occurred.

-

Total Cost of Ownership

The total cost of ownership is the overall cost of owning and operating a carton sealer and taper over its lifespan. This includes the initial purchase price, maintenance costs, and operational costs, such as tape and electricity. It's essential to consider the total cost of ownership when budgeting, as it can help you make an informed decision and choose a machine that meets your long-term packaging needs.

-

Machine Type

And finally, how much does each type of machine cost? What kind of warranty comes with it and is this guaranteed by the seller/manufacturer or by an outside company? Are there any hidden costs for repairs, maintenance or replacement parts that are not included in the price you pay for your carton sealer/taper? The type of carton sealer and taper you choose will affect your budget. Manual carton sealers and tapers are the most affordable machines and can cost as little as a few hundred dollars. Semi-automatic and automatic carton sealers and tapers are more expensive, ranging from a few thousand dollars to tens of thousands of dollars. The type of machine you choose will depend on your packaging needs, volume, and budget.

If you're working with a carton sealer and taper regularly, then these costs can mount up. It's worth considering whether this will be necessary before purchasing your machine so that you don't end up out of pocket when the time comes for repairs or maintenance visits.

Carton sealers and tape are used to seal boxes. Carton sealers are used to seal the top of a box while carton tapers are used to seal the bottom. The main purpose of using these carton sealing machines is to prevent moisture from entering or exiting the package which might spoil its contents. These carton-sealing machines can also be used for sealing other types of packaging materials such as plastic boxes and paper bags.