Key takeaways

- Drill rig prices range from $50,000 to over $1 million depending on size, depth capability, and technology.

- Types of drill rigs include auger drills, rotary drills, percussive drills, and sonic drills, each suited to different terrains and depths.

- Maintenance costs can average $15,000–$60,000 annually, depending on usage and rig type.

- Financing options often allow buyers to spread payments over 2 to 7 years, with rates starting from around 6.5% p.a. for business equipment loans.

- Warranties typically cover 12 months to 5 years, but extended warranties are often recommended for heavy use.

- Compliance requirements in Australia include AS/NZS 4801 (OHS Management) and ISO 9001:2015

- Top buyer considerations include ground conditions, depth requirements, rig mobility, local support availability, and financing flexibility.

Introduction

Purchasing a drill rig in Australia is a major investment that demands careful consideration. Whether you're drilling for mining exploration, construction, water bores, or geotechnical surveys, choosing the right drill rig can make or break your project success. In this guide, you'll find everything you need to make an informed decision, from the types of rigs available to pricing, maintenance, financing, compliance, and more. Let's dive in.

Types of Drill Rigs in Australia

Choosing the right type of drill rig depends on your project requirements, site conditions, and drilling depth. Here's a breakdown:

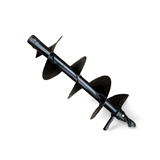

1. Auger drill rigs

- Best for: Soft ground, environmental sampling, shallow drilling

- Typical depth capacity: Up to 30 metres

- Price range: $50,000 – $150,000

2. Rotary drill rigs

- Best for: Water wells, mining exploration, oil and gas drilling

- Typical depth capacity: 100 metres to 3,000 metres

- Price range: $200,000 – $1 million+

3. Percussive (down-the-hole) drill rigs

- Best for: Hard rock, mining applications, deep hole drilling

- Typical depth capacity: Up to 1,000 metres

- Price range: $250,000 – $700,000

4. Sonic drill rigs

- Best for: Unconsolidated formations, environmental investigations

- Typical depth capacity: Up to 300 metres

- Price range: $500,000 – $1.2 million

Drill Rig Prices in Australia

Drill rig prices can vary significantly depending on several factors, including the type of rig, drilling depth capacity, mobility, brand, and included features. Here's a breakdown of what you can expect to pay for different types of drill rigs in Australia:

- Auger Drill Rigs: Starting from $50,000, with high-end models reaching $150,000. These rigs are ideal for shallow drilling in soft ground, such as environmental sampling or shallow water wells.

- Rotary Drill Rigs: Starting around $200,000, and for top-end models, prices can go up to $1 million or more. These rigs are used for deeper drilling, such as water wells, mining exploration, and oil and gas drilling.

- Percussive (Down-the-Hole) Drill Rigs: Typically starting at $250,000, with high-end models ranging up to $700,000. These are designed for hard rock drilling and are commonly used in mining and deep hole exploration.

- Sonic Drill Rigs: These rigs are specialised for unconsolidated formations and environmental investigations, starting around $500,000 and reaching up to $1.2 million for advanced models.

Factors that influence drill rig prices:

- Drill Depth Capacity: The deeper the rig can drill, the higher the price. Auger rigs are suitable for shallow applications, while rotary and percussive rigs are designed for much deeper holes.

- Power Source: Drill rigs with diesel engines tend to be more expensive than hydraulic models, especially for large-scale projects requiring a lot of power.

- Rig Mobility: Whether the rig is truck-mounted, skid-mounted, or trailer-mounted can affect its cost. More mobile rigs tend to be pricier due to the added convenience and versatility.

- Automation and Remote-Control Features: Rigs with advanced automation or remote-control capabilities will typically cost more, as these features improve operational efficiency and reduce the need for on-site personnel.

- Drilling Method and Tooling: Rigs designed for specific methods (e.g., rotary, sonic) may come with specialised tooling that adds to the cost.

Drill Rig Operations

Operating a drill rig requires trained personnel and adherence to strict safety protocols.

Key operational considerations:

- Operator training: Certified training is essential (eg. RII competencies).

- Drilling method: Air rotary, mud rotary, or down-the-hole hammer — each method suits different ground conditions.

- Support equipment: Compressors, mud pumps, and generators often needed.

Efficiency tip: Matching your drill rig to the right drilling method for your site's geology can improve speed and reduce wear by up to 30%

Drill Rig Maintenance

Maintaining your drill rig is critical to maximise uptime and lifespan.

Routine maintenance tasks:

- Daily visual inspections (hoses, fittings, fluids)

- Regular oil changes (every 250–500 operating hours)

- Lubrication of mast, rotation head, and hydraulic systems

- Replacement of worn-out drill bits and rods

Annual maintenance costs:

- Light use: $15,000–$25,000

- Heavy use: $40,000–$60,000

Financing Your Drill Rig Purchase

Financing a drill rig is a significant investment, but several options can make it more manageable. Here are the most common financing methods:

1. Equipment Loans

An equipment loan lets you borrow the money to purchase the rig and repay it over 3-5 years.

- Example: For a $250,000 percussive drill rig with a 5% interest rate over 5 years, the monthly repayment is about $4,700.

2. Leasing

Leasing offers flexibility with monthly payments and the option to return or purchase the rig at the end of the term.

- Example: Lease a $200,000 rotary drill rig for 4 years at $5,000/month. At the end, you can buy it for $50,000 or return it.

3. Hire Purchase

A hire purchase agreement lets you own the rig after completing the payments.

- Example: Finance a $300,000 rotary rig over 4 years with a 10% deposit ($30,000). Monthly repayments would be around $6,000.

4. Government Grants and Subsidies

Certain Australian government programs support equipment purchases that improve energy efficiency or reduce environmental impact.

- Example: The Clean Energy Finance Corporation (CEFC) offers low-interest loans for rigs with energy-efficient features.

5. Bank or Private Lender Financing

Traditional bank loans or private lenders can provide funding for drill rig purchases with fixed terms.

- Example: A $500,000 loan with a 4% interest rate over 5 years would result in monthly repayments of $9,200.

Warranties for Drill Rigs

Most manufacturers and dealers in Australia offer:

- Standard warranty: 12 months parts and labour

- Extended warranties: Up to 5 years for an additional cost

- Exclusions: Consumables like drill bits, rods, lubricants

Note: Some Australian suppliers offer extended warranty plans bundled with service contracts, which can save up to 20% compared to purchasing separately.

Compliance and Certification Considerations

Operating drill rigs in Australia requires adherence to various standards:

- Work Health and Safety (WHS) compliance: Under the Model WHS Laws

- Australian Standards:

- AS/NZS 4801 for OHS management systems

- ISO 9001:2015 for quality management

- AS 3785 (Hydraulic mining equipment - Safety)

- Licensing: Operators may require high-risk work licenses depending on jurisdiction

- Environmental compliance: Particularly if drilling near protected sites

Tip: Always verify the rig comes with a full compliance certificate and Australian engineering approvals.

Common questions drill rig buyers ask

How deep can a standard drill rig go?

It depends on the rig type. Auger rigs generally drill up to 30 metres, rotary rigs up to 3,000 metres, and sonic rigs around 300 metres.

Should I buy new or used?

- New rigs offer warranties, latest tech, and higher reliability.

- Used rigs can save 30–50% but may require immediate maintenance or upgrades.

How long does a drill rig last?

With proper maintenance, drill rigs often last 10–20 years or more, depending on usage intensity.

What certifications should a drill rig operator have?

Operators should hold RII qualifications (eg. RII20920 Certificate II in Drilling Operations) and have site-specific inductions.

How soon can I get delivery of a drill rig?

Lead times for new rigs can range from 3 to 9 months, depending on customisation. Used rigs can often be deployed within 2–4 weeks.

Final thoughts

Buying a drill rig in Australia is a strategic investment that demands careful planning. By understanding the different rig types, real-world prices, financing options, maintenance requirements, and compliance obligations, you can confidently select a machine that matches your operational needs and financial goals. Remember — spending the time upfront ensures long-term success on every project site.