Portable units are used for a wide variety of preventative maintenance inspection tasks and permanently installed infrared temperature sensors, also referred to as pyrometers, which are used to continuously measure the temperature of specific targets considered critical.

How do Infrared Sensors work?

All materials emit infrared radiation. The extent to which materials emit infrared radiation is based on the temperature of the material. Even cold objects emit infrared energy. Optical devices collect this infrared energy and focus the infrared “light” on to a detector that can measure the amount of energy.  That is then converted to a temperature as there is a direct correlation between the amount of infrared energy and temperature. It’s a lot more complex of course, but that is a quick description of the basic principle.

That is then converted to a temperature as there is a direct correlation between the amount of infrared energy and temperature. It’s a lot more complex of course, but that is a quick description of the basic principle.

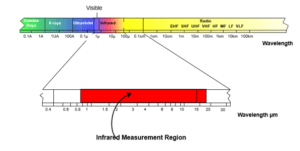

General purpose infrared temperature measurement devices will generally focus infrared light (not visible to the naked eye) in the region of 8 to 14µm – which is the description of the wavelengths that will be allowed to pass through to the detector element. As the temperature of materials gets to temperatures over 800 deg C, it is much better to use infrared sensors specially designed to measure the infrared light at lower wavelengths. Typically, 1µm, 1.6µm or 2µm wavelengths are chosen for temperatures above 1000 deg C – which is the domain of extremely hot metals and molten materials

What are the common problems?

We said above that materials emit infrared energy (or light) proportional to the temperature of the material. If the emitted infrared light increases, the temperature must be higher. If the emitted infrared light decreases, the temperature of the material must be cooler – WRONG

There are two causes of reduced infrared emissions – (1) cooling material temperatures, (2) something is obscuring the emitted energy.

If 100% of the infrared energy is emitted from the material surface but only 80% reaches the detector due to 20% being lost, then the infrared temperature measurement system will “measure” a temperature 20% lower than actual.

Typical causes of loss of infrared emitted energy are:

- Steam, smoke or other airborne atmospheric obstruction.

- Another material passes into the view path of the infrared pyrometer optics.

- Poorly focused optics not measuring the target wholly.

- Target object moves in and out of view

- Furnace pyrometers looking through dirty isolation windows that have buildup of contaminants

Some of these issues can be resolved if understood and options exist to affect a remedy.

Some of these issues cannot be resolved. It’s a problem that can’t be fixed.

Enter Dual Wavelegth infrared technology!!

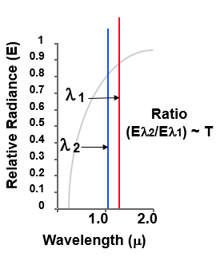

As the name suggests, dual wavelength infrared devices measure not one, but two different wavelengths simultaneously. It’s like two devices in one – but with a big difference. Whereas single wavelength devices (nearly all infrared measurement devices) determine the temperature by measuring the intensity of the emitted infrared energy, dual wavelength technology does not measure temperature by measuring the intensity of emitted radiation.

This is the key to why dual wavelength is a solution to infrared measurement problems created by energy is reduction/obscuration.

Dual wavelength devices measure the infrared energy at two different wavelengths. A ratio calculation between the two measurements is used to determine the temperature. As the ratio changes, so does the temperature. If there is any obscuration of infrared energy, errors impact both wavelengths equally and effectively cancelled out.

Dual wavelength infrared is therefore a necessity where targets are difficult to measure due to moving around or obscured. Ideal for installations where high temperature measurements require viewing through isolating windows to prevent flames and furnace emissions escaping. As the windows get increasingly dirty, the dual wavelength pyrometers continue to accurately measure temperature!!

Pyrosales represents Accurate Sensors Technologies (AST) infrared systems in Australia and we would be pleased to discuss any infrared temperature measurement applications with you