Whether in production environments or vocational training centres, these advanced pipe rotators have proven indispensable for safe, efficient, and precise pipe handling.

Engineered for Performance and Versatility

Pipe rotators are essential tools in the fabrication of pipes, tanks, vessels, and containers, transforming heavy and awkward components into smoothly rotating cylindrical workpieces. Kistler’s U-series, known for its durability and innovation, has remained one of the most popular and in-demand solutions in pipe processing and automated welding technology for decades. From high-volume production lines to technical training facilities, U-Range rotators are trusted worldwide for their:

- Easy and intuitive operator handling

- Exceptional flexibility in clamping various pipe geometries

- Smooth and precise rotation, even under offset loads

- Compatibility with both manual and robotic welding systems

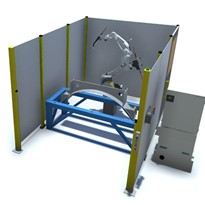

Ideal for Welding Training and Education

One of the standout benefits of the U-Range Pipe Rotators is their application in welding education and skill development. With hands-free operation, trainees can fully focus on learning proper welding techniques without having to manually manage the pipe.

We really like the performance, compactness, and smooth operation of the U150. The machine is a great addition to both every pipe processing workshop and training facility. — Don Eldridge, Training Coordinator

Key Features of the U-Range Pipe Rotators

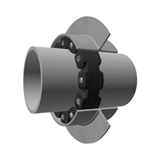

- Clamping Roller System (Patented) – Innovative system delivers fast, tool-free clamping without the need for chucks or clamping shoes.

- Wide Pipe Compatibility – Can handle elbows, Tee pieces, and various offset geometries without compromising rotational precision.

- Infinitely Variable Speed Control – The rotation speed remains consistent regardless of pipe size due to a dedicated drive unit.

- 360° Rotation with Tilting Functionality – Enables forward and backwards tilt from horizontal, independently or simultaneously with rotation.

- Precise Centring – Two pipes of the same diameter can be centred and aligned with minimal effort.

- Manual Height Adjustment – Each unit includes a standard manual vertical adjustment of the clamping roller, enhancing operational flexibility.

- Flexible Centre-of-Gravity Clamping – Pipes can be clamped at their centre of gravity, reducing stress and avoiding the need for support fixtures in most cases.

Applications

- Pipe fabrication and welding

- Vessel and tank manufacturing

- Structural steelworks

- Oil & gas industry

- Mining and heavy industry

- Welding education and training centres

-720x400.jpg)

-720x400.jpg)

-720x400.jpg)

-720x400.jpg)

-720x400.jpg)

-720x400.jpg)