1. What is a cantilever rack made of?

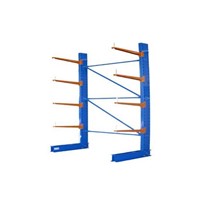

A cantilever rack uses upright columns connected with strong bases, arms and braces to store heavy products.

Upright is the rack footprint (the backbone) that consists of a vertical column and a horizontal base that is bolted to a column. They can be single-sided or double-sided. A single cantilever rack system needs a minimum of two uprights.

Brace sets are bolted laterally between the uprights in every cantilever rack to add stability to the system. Cross bracing is recommended when the uprights are taller to increase the stability of the cantilever racking system.

Arms (the heart of the rack system) vary according to your storage requirements. The changeable arms of cantilever rack systems allow storing odd-shaped inventory. Straight arms are usually used to store stable loads such as logs, cartons, sheets, etc. while inclined arms are used to store cylindrical items that could roll like pipes or tubes.

2. How do you install a Cantilever rack?

Here’s a stepwise method to install a Cantilever rack:

- Start by laying out the rack footprint i.e. the starter bay and horizontal base on the floor.

- Connect rack footprint to the upright columns. Make sure you bolt those columns to the base.

- Anchor the whole cantilever rack to the floor

- If you’re constructing multiple columns then connect the upright columns through brace sets for stability

- Connect the arms in the holes of the upright columns

- Add arm accessories according to your need.

3. What is the capacity of Cantilever racks?

Cantilever racks are an ideal and practical option for goods that are long and bulky so knowing the capacity can help you store the goods securely.

Cantilever columns have 500 to almost 60,000 pounds capacity depending on the arm strength. To calculate the capacity you can check the weight supported by each arm level and multiply it by the number of arm levels per upright column.

4. Can I customize the Cantilever racks?

Cantilever rack systems can be designed to be either roll-formed or structural steel depending on your requirements of length, weight and size. They can be customized with several other accessories to suit your warehousing needs.

Arms can vary in capacity and have end stops to keep the products from rolling off. Due to the varied styles and capacities available for these arms, cantilever racking systems are highly customizable for each application.

5. Can I reuse Cantilever racks?

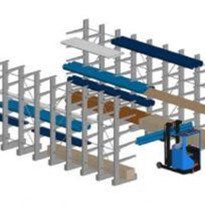

Cantilever racking uses all the dimensions of the available storage space — height, width and total area. If you want to stack long loads up to the ceiling and handle them with forklifts or equipment, Cantilever racking allows you to safely maneuver them.

Cantilever shelves are sturdy and have high reuse potential even if they are light-duty cantilever racks. If the used cantilever racks and shelves still meet design and safety standards, they can be removed, relocated and reused in other places.

6. What are the benefits of Cantilever racking?

- Cantilever racking is easy to install and configure

- Customizable arm configuration enables easy and quick adjustment to suit the height of goods

- It can accommodate long or awkward shape objects and allows additional storage possibilities for loads of all sizes and shapes

- Offers more accessibility while reducing the handling time

- High reuse potential so they can be utilized again in different places

7. What are the disadvantages of Cantilever racking?

- More expensive to get started in comparison to floor stacking

- It requires ample aisle space to allow forklifts and access to stored materials

- Inefficient for storing standard pallets

Cantilever Racking Systems

As industrial storage solutions become smart and automated, you can now adapt your storage space to suit diversified product types and warehouse operations.

Whether you’re located in Melbourne, Adelaide, Sydney, Brisbane or Perth, Cantilever storage systems are best if you want to accommodate large, bulky, long or oddly shaped objects that are otherwise difficult to store.

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)