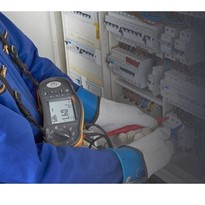

Proper grounding ensures excess electrical current safely dissipates into the earth, preventing equipment damage, injury, or fire.

In this comprehensive guide, we'll explore:

- What ground resistance testing is and why it matters

- The different methods of ground resistance testing

- A side-by-side comparison of some of the most trusted testers in the industry: AEMC 6471, 6472, 4620, 4630, 6422, and 6424

What is Ground Resistance Testing?

Ground resistance testing measures how efficiently a grounding system can conduct electricity to the earth. This is essential for:

- Protecting people from electric shock

- Preventing equipment damage

- Complying with electrical codes and standards (such as IEEE 81, NEC, and IEC)

- Ensuring lightning protection systems work effectively

- Ground Resistance Testing Methods

There are several methods to test ground resistance:

1. 3-Point Fall-of-Potential Test

The traditional and most accurate method using auxiliary electrodes (stakes). Best for system commissioning or installations with little electrical noise.

2. 4-Point Soil Resistivity Test

Used to measure soil resistivity, important for grounding system design.

3. Selective Testing

Uses the clamp-on method to eliminate the need to disconnect the ground system.

4. Stakeless Testing (Clamp-on Testing)

Fast and convenient for systems with multiple parallel grounds.

Comparing AEMC Ground Resistance Testers

AEMC is a leading manufacturer of high-quality electrical test equipment. Here's a detailed comparison of their ground resistance testers, broken down by model type.

AEMC 6471 vs AEMC 6472

Feature AEMC 6471 AEMC 6472

Test Types 2P, 3P, 4P, Selective, Stakeless All 6471 features + advanced capabilities

Soil Resistivity Yes Yes

Clamp-on Compatible Yes Yes

Earth Coupling Yes Yes

Bond Testing Yes Yes

Measurement Current >200mA >200mA

Communication USB USB

Display LCD, backlit LCD, backlit

Advanced Capabilities Soil resistivity auto calculation Potential measurement at stakes

Use Case Contractors, utilities Power utilities, industrial sites, engineers

Verdict:

Choose the 6471 for standard professional ground testing and reporting. Choose the 6472 for advanced diagnostics, analysis, and reporting.

AEMC 4620 vs AEMC 4630

Feature AEMC 6422 AEMC 6424

Test Method Digital 3P Testing Digital 3P Testing

Display Multi Line LCD Multi Line LCD

Test Voltage Fixed 10V Fixed 10V

Battery 6 x AA 6 x AA

Soil Resistivity No No

Portability Compact, lightweight Compact with more features

Ideal Use Budget-conscious testing Existing earth testing (3P)

Verdict:

The 6422 is ideal for occasional, budget-friendly testing. The 6424 offers digital precision and modern features for regular professional use.

Model Summary Table

Model Test Types Power Display Advanced Features Ideal For

6471 All major types incl. clamp Rechargeable Full Digital Leakage, coupling, bonding Utilities, inspectors

6472 All incl. diagnostics Rechargeable Full Digital Same as 6471 Engineers, industrial

4620 3P/4P Battery Digital Soil resistivity Contractors, electricians

4630 3P/4P Rechargeable Digital Weatherproofing Utilities, field techs

6422 Basic testing Battery Digital Compact Entry-level users

6424 Auto testing Battery Digital 2-Wire bond testing, 3P Electricians & simple use

Conclusion: Choosing the Right Tester

When selecting a ground resistance tester, consider:

- Environment – Wet or noisy conditions? Go rugged or advanced.

- Frequency of Use – Regular testing requires durability and ease.

- Compliance – For large infrastructure or compliance-driven industries, invest in models like the 6472.

- Budget – AEMC offers models from entry-level to premium for every budget.

Whether you're a contractor performing routine maintenance or a power engineer verifying complex grounding systems, AEMC’s lineup ensures accurate and reliable testing.

-720x400.jpg)

-720x400.jpg)

-160x160-state_article-rel-cat.png)

-205x205.jpg)

-205x205.jpg)