DRIVING FACTORS OF FORKLIFT INNOVATION

INCREASED DEMAND FOR FORKLIFTS

From 2022 to 2030, the global forklift market is expected to grow at a compound annual growth rate of 12.8%. This is due to the growth of e-commerce and online shopping, which was accelerated by the COVID pandemic and subsequent lockdowns. In addition, innovations in warehousing and the growing construction industry have also contributed to the demand for forklifts.

THE NEED FOR MORE EFFICIENT SUPPLY CHAINS

The booming e-commerce sector is increasing the number of warehouses and the need to efficiently manage supply chains. Also, warehousing and 3PL companies are striving to achieve lower operational costs and increased productivity. These factors are expected to boost demand for forklifts such as stand-up reach trucks and narrow-aisle forklifts, which provide high operation accuracy and better navigation in narrow aisles, tiers, and mezzanines.

DEMAND FOR ELECTRIC FORKLIFTS

The increased demand for electric forklifts is due to several factors, such as the rapid rate of innovation and technological advancements across all automotive industries, which can be readily transferred to forklifts. These innovative electric forklifts provide higher efficiency than internal combustion systems from load liability, acceleration, speed control on ramps, ability to negotiate a ramp and breaking.

Other factors that are boosting the interest in electric forklifts are the rising cost of fuel, more stringent regulations associated with emissions, sustainability initiatives, and the advanced technologies that electric forklifts can offer. They are also more popular in industries that require unpolluted air, such as chemical manufacturing, pharmaceuticals, and food and drink.

PRIORITISING WORKPLACE HEALTH AND SAFETY

Workplace health and safety necessitates that Australian businesses provide a safe work environment, as well as provide and maintain safe machinery and structures. Because forklifts are among the most dangerous vehicle types in the workplace, there has been increased pressure on businesses to invest in safer solutions.

EMERGING INNOVATIONS IN THE FORKLIFT INDUSTRY

Given these driving factors, these are the innovations that are ongoing and upcoming in the forklift industry:

MORE SAFETY FEATURES

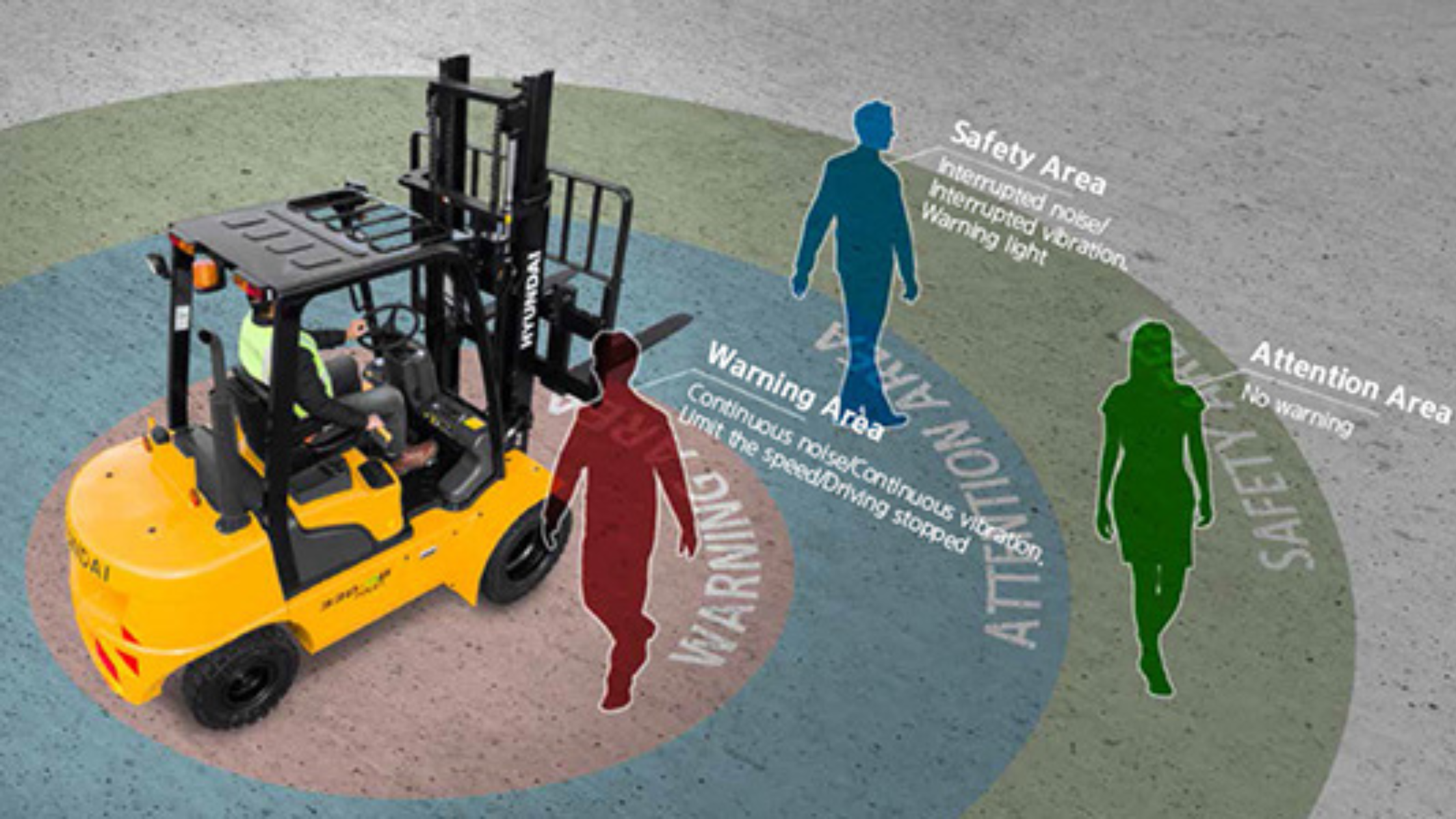

There have been numerous safety innovations to meet the demand for safer workplaces. In addition to the standard horn, lights, overhead guards, seatbelts, and breaks, there are now more proactive safety features that can provide peace of mind to forklift drivers, business owners, and pedestrians. Hyundai Forklifts, for example, are packed with features such as curve control, stability systems, Fork Lower Control, Intelligent Proximity Alert System, tilt levelling systems, weight indicators, hill start assist control systems, fork cameras with LCD monitors, and much more to ensure your business is future proof.

EMISSION REDUCTION

Electric forklifts have been around for a while, but the most notable change is the transition from lead-acid to lithium-ion batteries. Some of the perceived negatives of battery forklifts such as the charging time, maintenance (refilling water), and inability to opportunity charge are no longer an issue with lithium-ion batteries because they charge faster, require no maintenance, and can be charged at any time.

Hydrogen-powered forklifts are another emerging innovation! A hydrogen fuel cell forklift's only byproducts are water and heat. In contrast to internal combustion engine forklifts, which emit a variety of harmful glasshouse gases, hydrogen fuel cell forklifts are safer for operators and the environment. Furthermore, charging a hydrogen fuel cell forklift takes only minutes, resulting in less downtime and higher productivity.

A joint initiative from several Hyundai companies has developed and intends to commercialise a hydrogen forklift in the coming years.

AUTONOMOUS FORKLIFTS

The expanding e-commerce industry is putting strain on all levels of logistics, with demand going unmet due to human resource issues such as working overtime, which reduces efficiency and increases risk. As a result, automated logistics systems and self-driving forklifts have been developed. Because they do not fatigue, autonomous forklifts can work 24 hours a day, seven days a week, significantly increasing warehouse productivity. They can reduce workplace risk because many forklift-related accidents are caused by negligence or a fatigued worker. Finally, they can boost efficiency because the software can quickly calculate the shortest moving path at that time. Hyundai unveiled its new autonomous forklift in 2019 and is continuing its development.

Hyundai High Performance Forklifts is at the forefront of technology, safety and environmental protection. Contact the team at Hyundai High Performance Forklifts today to see how you can future proof your business.

Equipment financing experts' insights for businesses in 2023

Have rising interest rates and inflation led you to question if investing in assets is a good idea? You are certainly not alone. This week, we spoke with George Rikiti, an expert on equipment financing, about the current economic climate, how it affects Australian businesses, and his advice for businesses trying to navigate the current economic climate.

-160x160-state_article-rel-cat.png)

-205x205.jpg)