They are vital components that bridge the gap between a heat source and desired temperature, enabling fine-tuned control of heat generation. In numerous industries, including cement production, steel manufacturing, cosmetics, textiles, and electronics, temperature controllers play a pivotal role in achieving consistent and efficient manufacturing processes.

Key components of Process Heating Systems.

Process heating systems are responsible for suppling heat during various manufacturing processes and consist of four primary components:

Heat Transfer Devices: These devices transport heat from its source to the materials or product requiring heating, ensuring even distribution of heat.

Heat Generation Devises: Responsible for generating and supplying heat to the system, these devices must operate with efficiency and precision to maintain the desired temperature levels.

Heat Recovery Devises: Heat recovery systems capture and recycle excess heat, enhancing energy efficiency and reducing operation costs.

Heat-Containing Devices: This category includes heaters, furnaces, kilns, and ovens, which maintain the required temperature within the manufacturing process, ensuring consistent and reliable results.

To achieve precise temperature control within these systems, additional support systems are employed, including temperature sensors, temperature controls, process atmosphere control, and material handling systems.

RKC Temperature Controllers in Process Heating.

RKC Temperature Controllers are a recognized leader in the field of industrial control, Pyrosales is a recognised distributor for the controllers. We provide a range of temperature control solutions tailored for process heating applications. In particular, the focus is on RKC SSN PA and ZC Power Controllers, which offer a host of advantages:

RKC Temperature Controllers are a recognized leader in the field of industrial control, Pyrosales is a recognised distributor for the controllers. We provide a range of temperature control solutions tailored for process heating applications. In particular, the focus is on RKC SSN PA and ZC Power Controllers, which offer a host of advantages:

Precision Control: RKC controllers excel in providing precise temperature regulation, a critical feature for maintaining product quality and process consistency.

Thermal Fatigue Elimination: The SSN RKC series controllers are designed to eliminate failures caused by thermal fatigue, a crucial benefit in applications involving frequent on/off cycle.

Control Resolution: RKC controllers offer fine control resolution, allowing operators to make minute adjustments to temperature settings. This level of precision is crucial in processes where tight temperature control is paramount.

Avoidance of Side-Effects: SSN PA and ZC controllers are engineered to prevent side effects, such as light flicker, a common issue when dealing with high in-rush electrical currents, thus ensuring a stable and reliable heating process.

Application Flexibility: RKC controllers are adaptable to a wide range of application, from smaller single-phase loads to more substantial three-phase arrays. This versatility makes them suitable for various manufacturing processes with differing power requirements.

Selecting the Right RKC Temperature Controller

Choosing the most suitable RKC temperature controller and accessories for a process heating application hinge on several factors:

- The specific demands of the process

- The type of heating method utilized (e.g., steam, electric, fuel-fired, air/water/oil)

- The required level of temperature control precision.

In addition, process heating requires several other supporting systems. Such as temperature controls, temperature sensors, process atmosphere and material handling. Pyrosales can design your total temperature solution throughout the process heating system. We use RKC Controllers, RKC Accessories, and manufacture temperature sensors in the solution.

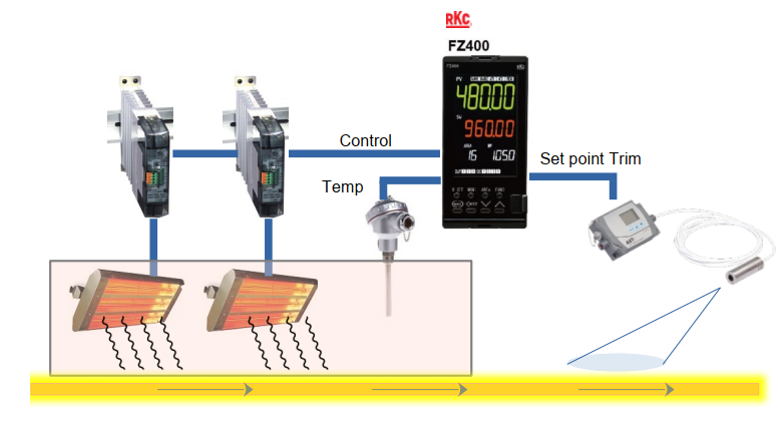

An example of a solution:

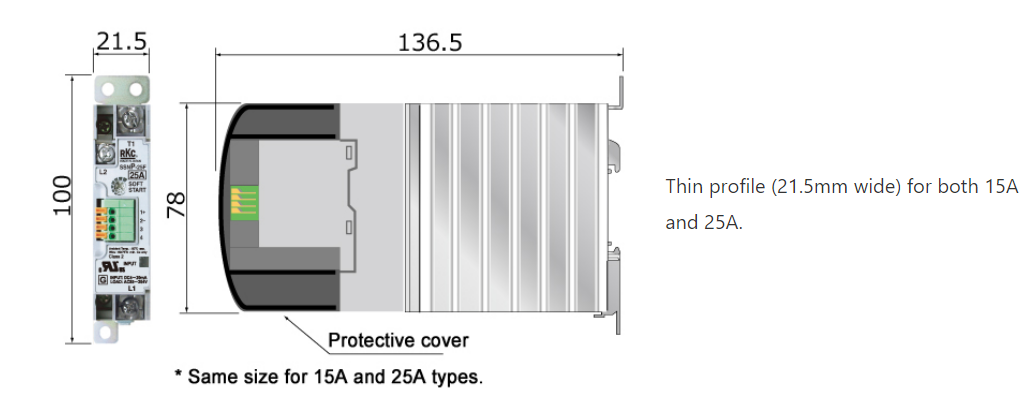

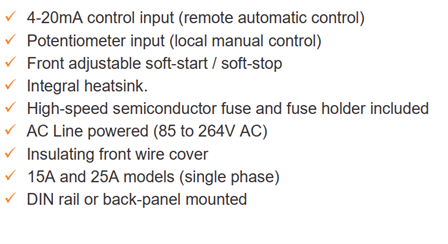

RKC SSN PA and ZC Power Controllers.

The precision application of short-wave and medium-wave heating power can be challenging on solid state power control components due to high in-rush electrical currents.

Short-wave and medium-wave heating systems require consideration in temperature control system design including the correct selection of the electrical power regulating devise.

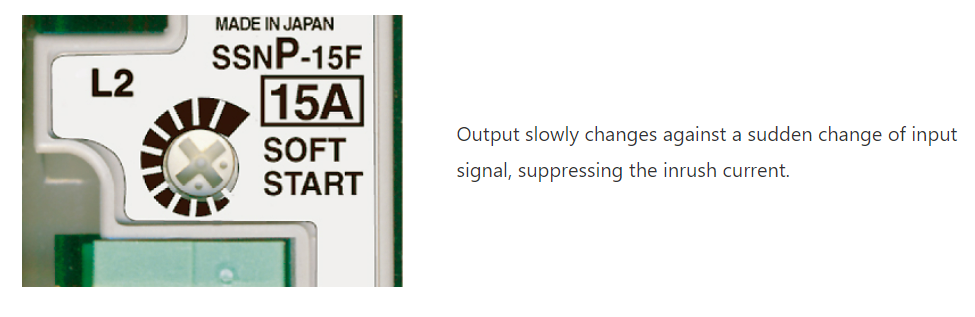

RKC SSN series Phase Angle (PA) and Zero Cross (ZC) eliminates failure from thermal fatigue, increases control resolution and avoids side-effects such as light flicker.

Idle for smaller applications – single phase loads to 6kW and up to 10.4kW in three phase arrays (multiple SSN units require 3-phase control) SSN-P and SSN-Z SSN P – Phase Angle firing mode SSN Z – Zero Crossing firing mode

Pyrosales has extensive knowledge and experience in temperature management and process control. We provide advice, design, repair, and fabrication to our clients on a wide range of industries, uses, and capabilities of temperature management.