The accumulation of excess dust in a compressed air system can have several negative effects. Over time, dust can lead to a decrease in performance as particles flow into the compressor’s moving parts and reduce their efficiency.

Dust can cause a decrease in air pressure, interfere with the proper functioning of the compressor’s internal components, and end up costing you time and money.

So how can you manage contaminants like excess dust?

Solutions To Prevent Excess Dust From Entering Your Compressed Air System

Dust Filters

Excess dust can easily be pulled in by the compressor, travelling through into your compressed air system. However, installing dust filters before the compressor stops dust before it enters the system, protecting downstream compressed air systems and equipment.

Moisture, dust, and other contaminants can accumulate on the valves, rotors and vanes of the compressor, resulting in premature wear, reduced compressor capacity and unnecessary expenses for your business, which is why compressed air filtration systems are an integral part of an efficient design.

Particulate filters can be installed adjacent to the compressor, with models such as our 0.01 Micron Post Filters & Filter Housing offering 99.99% efficient filtration. A three-stage (Pre, Post, and Activated Carbon Filter) system delivers clean compressed air that is equipment-ready, removing dust, water vapour, microbes, aerosols, and other contaminants in your airlines. A 1 micron version is also available, offering the same efficiency.

Replacing the air filter in your compressor at least every 6 months will not only prevent the build-up of excess dust and debris within the filter but ensures the air supplied to the pneumatic tools and machinery from the compressor is clean. In turn, this simple preventative maintenance task will protect your equipment from potentially irreversible damage and ensure your air quality and pressure remains optimal.

Environmental Controls

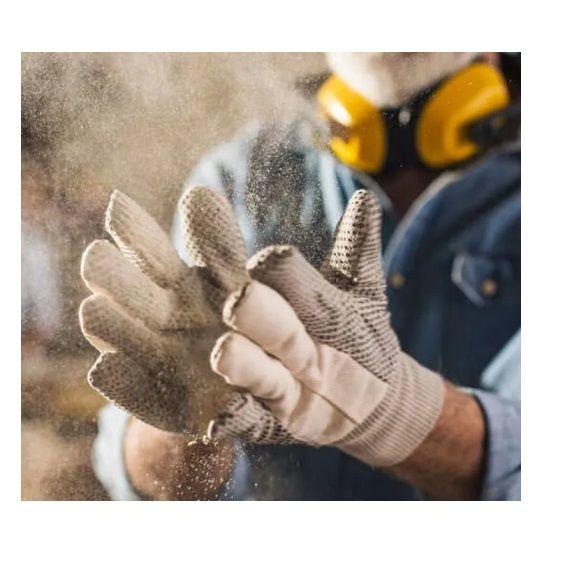

Dust particles can migrate across the most tightly-sealed environments, making it difficult to keep 100% of dust away from your compressor.

Even in a dedicated plant room away from the work area, dust can quickly accumulate and enter your compressed air system, resulting in a compressor that shows warning signs such as reduced air pressure, an increase in noise and vibration, and overheating. This is a particularly common issue in environments such as timber joinery workshops and dusty warehouses. And at the right concentrations, dust is explosive, which can end up damaging the internal components and necessitating costly repairs.

This is why the right dust-free location for your compressor is an important consideration. Always aim to ensure the air intake is located in an area that is protected from dust, fumes and humidity, and keep the area clean.

Get Personalised Advice On Air Compressor Efficiency Such As Managing Excess Dust

Compressor performance can drop considerably if the unit is not regularly cleaned of dust and debris: not only does dust build-up encourage poor air quality, but by reducing efficiency, it causes your energy costs to skyrocket and creates unnecessary repair costs.

If you’re not sure if your compressed air system is clean and running efficiently, our servicing program can help you address any underlying issues, ultimately reducing excess power demands, preventing reworks due to poor compressor output, reducing your carbon emissions, and ensuring you get the most out of your investment.

Contact our expert team to find out more about air compressor servicing.