The gas shields the arc, the tungsten electrode is not consumed by the arc, but it does provide a transition point for the arc. The arc heats the metal. When the metal is at the appropriate temperature a similar metal filler rod can be introduced into the arc to provide a puddle of molten metal to fill the weld joint.

AC DC welding

There are two modes of TIG welding:

- Direct Current (DC), used for all metals except Aluminium, and magnesium alloys.

- Alternating Current (AC) used for Aluminium and magnesium alloys only.

The first question then is “Is aluminium welding a requirement?”

If yes, then a machine capable of AC is required. Most modern AC welding machines are inverter types, which also have DC capacity. So, an AC/DC TIG machine will be able to weld most metals. If welding of aluminium is not necessary, then a DC-only TIG machine will be suitable.

Gas delivery

TIG welding requires insert gas shielding, so a method of connecting gas and introducing it into the weld is required.

More sophisticated machines will have an in-built gas valve, which the machine will turn on when the torch trigger is pressed. These machines will usually have added features of post gas and pre-gas where the user can set a time – usually seconds – to add gas to purge the weld areas before welding is started, and continue gas flow to prevent oxygen contaminating the weld pool, and allow weld pool cooling at the end of the weld.

The less sophisticated machine has no in-built gas valve and will require a torch with in-built manually operated valve.

Another question to ask yourself is, ‘how much TIG welding is going to be done, and are the benefits of a gas valve needed?’

If TIG welding is the main task, then a machine with a gas valve will be necessary. If TIG welding is only required for occasional jobs, or a long-weld job, i.e. in cladding applications, then the manual gas valve might be quite adequate.

Arc Starting

For TIG welding arc starting is a major consideration. There are three styles of starts.

Scratch start

This is an older style of starting technique usually associated with a transformer type machine. Not as common now with inverter machines.

Lift start

This type of start is possible with an inverter machine. The tungsten is gently touched on the job, the control circuit senses the touch and waits for the tungsten to be lifted off the job, and then quickly ignites the arc for welding.

HF start

The HF start allows the arc to be started without the tungsten touching the job. This feature can be important if the risk of tungsten contamination of the job is an issue, like pressure vessel welding.

Remote Control

There are four different scenarios for remote control of TIG machines:

- No remote control – starting is by lift arc, gas is by manual valve, current adjustments is set using the machine control panel.

- Remote torch trigger control – starts the pre-gas sequence HF start, or lift arc. Then end of weld sequence.

- Remote torch trigger and current control – the torch remote trigger starts the pre-gas sequence HF start, or lift arc. Current adjustment can also be controlled from torch during welding, which can be useful to control the heat into the weld, particularly aluminium where extra heat is required at start of weld to preheat.

- Remote foot control of arc starts and current – foot control unit can be connected to the machine via the same connector as the remote torch. Pressing the foot control pedal starts the arc, then further depressing of the pedal increases the current. This allows hands-free current control and fine adjustments while welding.

AC welding features

AC welding inverter machines uses high current electronic switches, usually IGBT, to create an AC weld output.

The AC frequency can be varied, typically to 30-150Hz. A high-frequency AC can be used to focus the arc, which is useful on thin material and tight corners. Good control of AC balance, or the amount of positive cycle to negative cycle, is important. Changing the balance is important for effecting the amount of surface cleaning the arc performs.

Machine size

Determining what size machine can be a balance between daily use expectation and possible one-off, large job expectations, as well as cost. If only welding thin wall steel tube, a 140A might be quite adequate, whereas 5mm aluminium would require at least 200A.

Duty cycle

The duty cycle of a machine is an indication of the machines ability to operate for extended time. The duty cycle is defined as the time the machine can operate at maximum output in 40C ambient temperature, over a 10-minute cycle. The duty cycle is expressed as a percentage. So, a 20% duty cycle, is maximum current for two minutes, then eight minutes with no current, then repeat.

If the output current is lower than, the duty cycle is increased. The machine specification will give maximum duty cycle, and current, 100% duty cycle current, and often 60% duty cycle current. This data will help determine requirements.

If the application is a lot of small joints each requiring some set up time then, a duty cycle of 20 per cent will quite adequate. When welding large cladding jobs, then a higher duty cycle would be recommended.

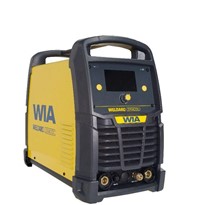

A good starting point for choosing a good welding machine is the Miller range from Welding Industries of Australia. There are seven units in its Arc and TIG welding series, which are suitable for a range of applications such as maintenance, marine welding and sheet-metal welding.