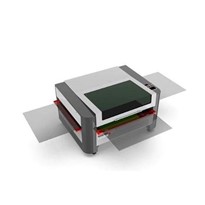

Investing in a laser machine can be a game-changer for businesses in manufacturing, signage, engraving, and personalisation. But with so many options available, how do you choose the right one? Selecting the best laser machine depends on your specific needs, materials, and long-term goals.

Let’s break it down.

1. Understand Your Business Needs

Before selecting a machine, ask yourself:

- What materials will I be working with? (Wood, acrylic, metal, leather, glass?)

- What is my primary focus? (Engraving, cutting, or both?)

- How much production capacity do I need? (Small-scale, mid-size, or high-volume production?)

2. CO2 vs. Fiber Laser, Glass tube or RF tube lasers? Which One Suits You?

- CO2 Lasers – Ideal for cutting and engraving wood, acrylic, leather, and glass. Perfect for signage, custom gifts, and creative industries.

- Fiber Lasers – Best for marking and cutting metals (stainless steel, aluminum, brass). Used in industrial manufacturing, jewellery, and tools.

- Glass Tube vs. RF-Tube Lasers – Glass tube lasers are cost-effective and suitable for general cutting and engraving applications, but they have a shorter lifespan and lower precision compared to RF-tube lasers, which offer enhanced performance, longevity, and precision, making them an excellent choice for high-end engraving and cutting applications.

At Prytec, we offer both glass tube and RF-tube laser options to cater to the diverse needs of our customers.

3. Key Features to Consider

- Laser Power: Higher wattage means faster cutting and deeper engraving. (Example: A 100W laser is great for thick materials.) Bed Size: Consider the size of materials you’ll be working with. Larger beds offer more flexibility.

- Speed & Precision: A machine with high engraving speed and cutting accuracy saves time and improves quality.

- Airflow Control & Safety Features: Proper ventilation, air assist, and enclosed designs enhance safety and performance.

- Power Requirements: Some laser machines require complex power setups, but with Prytec, no special power setup is necessary; Our laser machines run off a standard GPO 10A power socket.

4. Australian-Made vs. Imported Machines

Why choose Australian-made?

- Certified quality & reliability

- Local support & warranty

- Compliance with Australian standards

At Prytec Solutions, our machines are proudly designed and engineered locally, backed by in-house R&D that drives continuous innovation. This ensures unmatched precision, efficiency, and durability, making them the perfect choice for businesses looking to scale. We also provide local support, installation, and training to help you get the most out of your investment.

5. Graphics Software Compatibility

Many popular graphics software programs work seamlessly with Prytec laser machines and the LightBurn software provided with the laser. Some of the commonly used software include:

- CorelDRAW

- Adobe Illustrator

- AutoCAD

- Inkscape

- LightBurn

6. Making the Right Investment

A laser machine isn’t just a tool; it’s an investment in your business growth. Choosing the right one ensures higher productivity, better quality, and increased profitability.

Need expert advice? We’re here to help you find the perfect fit. Let’s discuss your business needs and get you set up for success.