Item transfers and handling may seem like a trivial task but it can make or break your supply chain during high-volume production or peak seasons. This dilemma often leaves business owners grappling with the decision between investing in manual or electric pallet jacks.

Choosing the right equipment for your business can make all the difference in operational efficiency, safety, and cost management. That’s why it’s only natural to take time deciding which equipment to invest on, especially with budget constraints and financial risks.

In this article, explore the different factors or angles that you should look into when comparing the impact of manual and electric pallet jacks for your business.

Key Differences Between Manual and Electric Pallet Jacks

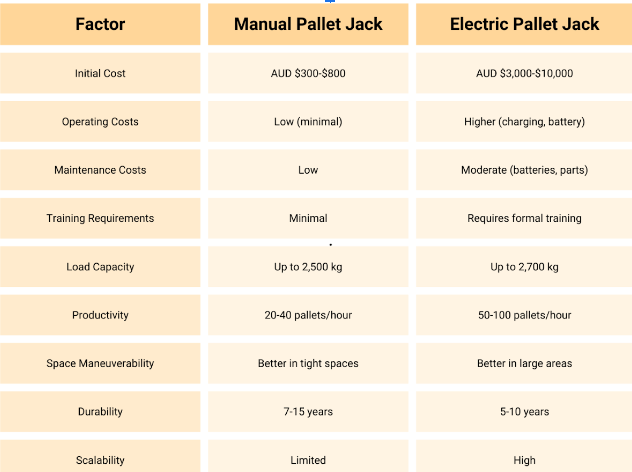

Electric pallet jacks, also known as electric pallet trucks, offer a significant advantage over manual options in many areas. However, before you invest in a new or used electric pallet jack, it's important to understand the factors that differentiate them from manual pallet jacks so you can decide which fits your business and budget.

Power, Operation, and Load Capacity

The distinct difference between manual and electric pallet jacks is in their power source. Manual pallet jacks rely on human strength to push or pull the load. On the other hand, electric pallet jacks, powered by a motor, excel at handling heavy lifting and transporting loads over extended distances.

Electric pallet jacks can handle significantly heavier loads, ranging from 900 to 2,700 kgs, while manual jacks max out at around 2,500 kgs., depending on the operator’s strength.

Due to their weight capacity, electric pallet jacks are more suitable for larger warehouses or operations moving a high volume of goods. Meanwhile, manual pallet jacks can only handle lighter loads that makes them a better fit for smaller businesses or in industries where heavy lifting isn't a daily requirement.

In terms of power source and ease of operation, electric pallet jacks have the upper hand in reducing operator fatigue, handling heavy or more items, and boosting efficiency in transporting goods across facilities.

Maneuverability in Different Spaces

Both electric and manual pallet jacks offer unique advantages in terms of manoeuvrability or ease of use. Electric pallet jacks are equipped with motorised controls that make them easier to use in spacious areas or travel long distances.

In smaller spaces or crowded aisles, a manual pallet jack would be more practical due to its compact size and ability to do tight turns. Therefore, it's crucial to consider your facility's layout and space when deciding which type of pallet jack best suits your operations.

Impact on Worker Productivity and Safety

Electric pallet jacks are designed to reduce physical strain on workers, which can lead to fewer injuries and higher productivity. With motorised lifting strength, they can transfer and move approximately 50-100 pallets per hour.

In contrast, manual pallet jacks require skill and physical effort, which can slow down operations and increase the risk of worker injuries. They can only handle around 20-40 pallets per hour which is 2 to 3 times less than their electric counterparts. As a result, manual jacks may not be sustainable for handling high-volume products or for daily heavy lifting.

If your business prioritises employee well-being and adaptability to volume surges, electric pallet jacks provide a safer and more productive option.

Cost Considerations and Budget

When it comes to cost, manual pallet jacks have a lower initial purchase price and reduced maintenance costs. They are always a practical option and ideal for startups or small to medium businesses on a budget.

Manual pallet jacks cost around AUD $300-$800 and have minimal to no maintenance or repairs. Second-hand options are also available and can be as low as AUD $100 to $400. The only catch with manual pallet jacks is you need to hire staff that can handle heavy lifting which translates to labour costs.

On the other hand, brand new electric pallet jacks cost around AUD $3000-$10000 and come with operating costs such as charging, battery maintenance, and parts replacement.

Electric pallet jacks may require a higher upfront investment and operational costs. However, the savings lie in their long-term benefits, such as increased productivity and time saved. All of which can offset the big initial expense.

Here are other cost considerations in investing on electric pallet jacks:

- Electricity costs (charging costs)

- Battery replacement (one battery lasts for 3 to 5 years)

- Maintenance costs

- Operator training costs

- Insurance

- Downtime costs

- Annual depreciation

One compromise that most business owners consider is purchasing a used electric pallet jack that costs less but is still reliable and functional. They are usually around AUD $2000 to $7000. With used electric pallet jacks, you don’t need to hire specialised labour and they can provide a more budget-friendly entry point while still offering the benefits of a new model.

Worker Skill Requirement & Training

One important factor to consider is the level of training required to operate each type of pallet jack. Operating a manual pallet jack is straightforward and generally does not require skill or specialised training to use. However, workers need to have physical strength to handle both light and heavy loads.

In contrast, electric pallet jacks require operators to undergo training, as mandated by Safe Work Australia. The required training ensures that workers are well-versed in the safe operation of powered equipment to reduce or avoid any accidents. Therefore, there are training costs involved.

Maintenance and Durability

Manual pallet jacks are simple and have low maintenance needs. They do not have electrical components that can break down, making them a budget-friendly choice for many businesses. Their average lifespan can last around 7 to 15 years depending on how and where it is used.

Electric pallet jacks, while more efficient and powerful, do require regular maintenance of their electrical systems, batteries, and motors. Due to heavy use and motorised nature, they can last for 5 to 10 years which can be extended with routine maintenance care and replacement of worn out parts.

When purchasing an electric pallet jack, consider the availability of parts, warranty options, and the cost of routine maintenance to ensure long-term reliability.

Scalability and Future Growth Needs

The last factor to consider is the current state and growth projections of your business. If your operations are likely to expand in your growth phase, investing in an electric pallet jack may provide a scalable solution that can handle increased workloads and larger spaces.

If your product volume has been consistently increasing over the past six months and your fulfilment process is struggling to keep up, that is probably one of the good indications that an upgrade to an electric model can be the best option.

On the flip side, if your business is at a moderate growth rate and doesn’t require too much heavy lifting, manual pallet jacks might still be a sufficient solution.

As your business scales, electric pallet jacks can seamlessly handle larger volumes and extended operations, whereas manual jacks may become a bottleneck on your efficiency and growth potential.

Before you start looking for pallet jack models, it's important to consider the risk attached to every capital investment on equipment. Make sure that the purchase doesn’t eat a large chunk of your cash flow and always anticipate a specific threshold or buffer of costs.

Here’s a simple decision-making table to help you in deciding for your capital investment on electric pallet jacks.

Discover the Best Pallet Jack for Your Business with IndustrySearch

When it comes to business, an upgrade doesn’t always mean growth. It can also mean risks that business owners take to prepare for the future. Every equipment must meet every business need and budget that’s why it’s understandable that business owners take time to decide.

Are you still at the crossroads on which equipment to consider?

Don’t let indecision hold back your operations. Empower your purchase decisions by getting a tailored quote from Australia’s best electric pallet jack suppliers through IndustrySearch today.

With more insights, you’ll achieve informed decisions with confidence, knowing you're backed by the best in the industry.

.png)

-160x160-state_article-rel-cat.png)